Lithium-ion batteries have reigned supreme for two decades now. They’re easily rechargeable, versatile and long-lasting. They even made cell phones and laptops possible. As early electric vehicles like the Nissan Leaf and Chevy Volt began production, the use of Li-ion batteries skyrocketed. But in the world of technology and engineering, there’s always something newer and better. While Li-ion batteries have been driving electrification, engineers have been hard at work in the background, eagerly trying to bring its likely successor, the solid-state battery, to mass production.

Solid-state batteries have been called the next frontier in electric mobility. Could EVs with 500-mile ranges and 10-minute charge times be right around the corner? Automakers are funneling billions of dollars into the research and development of these game-changing batteries and the challenge of manufacturing them at scale. Whether or not consumers will ever see the benefits of EVs powered by solid-state batteries remains to be seen, but OEMs are closer than ever before to the ‘holy grail’ of electrification.

How Are Solid-State Batteries Different Than the Status Quo?

First, battery basics. Batteries contain two electrodes, a cathode and an anode. Connecting the electrodes is an electrolyte, which is a material that conducts electricity between the two electrodes. Lithium-ion, alkaline and most other existing battery types use a liquid electrolyte. Solid-state batteries, on the other hand, replace the liquid electrolyte found in other batteries with a solid electrolyte. Some labs are toying with inorganic ceramics for their electrolyte, others are trying it out with polymers. In essence, most of today’s batteries are ‘wet batteries.’ Solid-state batteries are ‘dry’, and with that comes many benefits, but also some new challenges.

Why are automakers so intent on revamping their battery packs?

It comes down to 4 things: safety, efficiency, durability and cost savings.

Safer EVs

Rigorous analyses show that EVs are less prone to vehicle fires than combustion vehicles, with notable exceptions. Still, Li-ion batteries are susceptible to short-circuiting when abused, a big problem that can lead to fires. Moving beyond liquid electrolytes to solids could reduce the risk of battery-related vehicle fires.

In the World of EVs, Efficiency is King

While battery density is decent in Li-ion batteries, laboratory research shows that solid-state batteries are far superior (up to 10x greater in experimental cells). Should solid-state batteries make it to mass production, OEMs will be faced with deciding whether to produce cars with massive ranges (400-500 miles), or producing cars with decent range (250-350 miles) that require smaller battery packs than today’s EV models. Smaller packs would save money, but larger ranges would likely boost sales.

Durability = Sustainability and Savings for Consumers

Today’s EV batteries degrade slowly with mileage. Anyone who has owned an early Nissan Leaf or Tesla Model S knows that well. It’s common for an EV to retain 80% of its original EPA-rated range after driving 100,000 miles, but some models fare worse. Solid-state batteries could change that. Any technology that boosts reliability and durability will be a welcome addition for consumers on the market for an EV.

Affordability Is the Only Thing That Will Bring EVs to the Masses

Back in 2015, Tesla was achieving battery production costs of about $150 per kilowatt-hour. That translated to a 100 kWh battery pack that cost $15,000 for the Model S. At the time, Elon Musk knew that battery production would have to become far more affordable before EVs could approach cost-parity with combustion vehicles. He and others in the emerging EV industry set the ambitious goal of $100 per kWh. Today, that goal has been reached for some automakers, including Tesla.

Even with this monumental accomplishment, EVs are still a bit expensive. With affordability and engineering achievements in mind, the US Department of Energy thinks that $60 kWh batteries are within reach. A part of reaching that goal in this decade will be the mass production of a far more efficient battery. Solid-state technology could be the key.

Get the most when you sell your car.

Compare and choose multiple offers in minutes:

Which OEMs Are Developing Solid-State Batteries?

Despite the promising headlines, not everyone is convinced that tomorrow’s EVs will be powered by solid-state batteries. For those that are, partnerships and startup acquisitions have been central to their strategies. Here’s where major automakers stand in future battery research and development:

Toyota Solid State Battery

Toyota is investing $13.5 billion in new battery tech, including solid-state batteries. They’ve been working hard to bring solid-state to mass production for several years. Toyota’s battery engineers cite ongoing issues with limited service life as a remaining obstacle, but a working prototype may hit the test track in 2023. Unlike some, Toyota is not taking a sharp turn towards an EV-only lineup. Leadership has indicated that they’re playing the long game, and they are confident that their investments will pay off in the long run.

General Motors Solid State Battery

General Motors has a stated goal of 60% lower battery costs for the second generation of its new Ultium EV platform. On top of GM’s massive EV investment, the General recently announced a new $5 billion battery development facility in Michigan. GM says the new facility will “allow GM to accelerate new technologies like lithium-metal, silicon and solid-state batteries, along with production methods that can quickly be deployed at battery cell manufacturing plants.” It sounds like GM is playing it safe and would rather not put all of its battery ‘eggs’ in one basket.

Ford Solid State Battery

Ford is laser-focused on solid-state. Ford’s engineers say that solid-state batteries “can be made on today’s lithium-ion battery lines, allowing Ford to reuse about 70 percent of its capital investment in lithium-ion manufacturing lines.” They’re taking the partnership route, teaming up with both SK Innovation and Solid Power to bring solid-state batteries to their EVs in the latter half of the 2020s. Ford recently announced plans to build a $11.4 billion battery production facility with international battery R&D leader SK Innovation. At about the same time, Ford also announced that it is boosting its investment in Solid Power, another promising solid-state battery developer. “By simplifying the design of solid-state versus lithium-ion batteries, we’ll be able to increase vehicle range, improve interior space and cargo volume and ultimately deliver lower costs and better value for customers,” shared Ted Miller, Ford’s manager of electrification subsystems and power supply research.

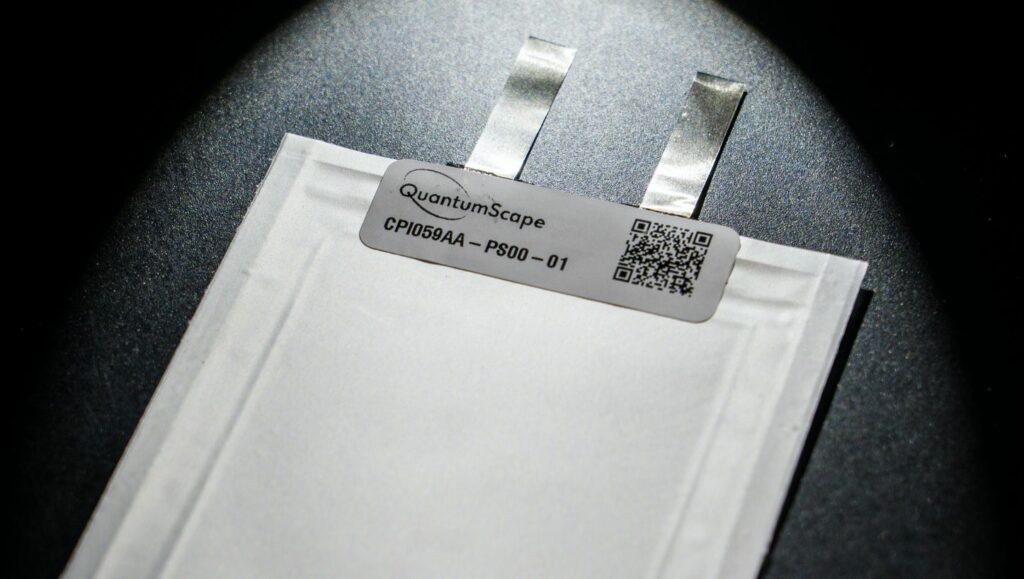

Volkswagen Solid State Battery

In 2019, Volkswagen Group launched a partnership with QuantumScape, a Stanford University startup that is a leader of solid-state development. QuantumScape claims to be close to a scalable solid-state battery, and VW hopes to bring it to production in late 2024 or so. VW opted to increase its investment in QuantumScape by an additional $200 million in 2020 for a total investment of $300 million, so it looks like the world’s largest automaker is sure of its footing in battery development.

Partnerships with Factorial Energy

Hyundai-Kia, Stellantis and Mercedes-Benz have all entered into separate partnerships with Factorial Energy, a Massachuesetts-based battery tech startup with promising solid-state battery development. Stellantis wants to roll out solid-state technology in 2026, but some industry experts are skeptical of such a quick timeline.

Why Are Solid-State Batteries So Hard to Make?

If this technology has been in the works since 1978, why aren’t solid-state batteries already in cars? Partly, it’s because Li-ion batteries work just fine for most applications. The mass adoption of EVs is accelerating, and the limitations of Li-ion battery charging speed, durability and thermal management are driving the latest push to find something better.

There have been major achievements in battery technology over the years. Decades of research went into the creation of a stable solid-state electrolyte, and many great options have been developed. Now, improving durability and manufacturing techniques are the main challenges.

Early prototypes have been plagued with problems like damage after repeated charging. Some of the damage is due to dendritic growth that can short-circuit the battery, leading to thermal runaway (a fire!). Dendritic growth is a risk with current liquid electrolyte batteries, but it was long thought that solid electrolytes wouldn’t be susceptible. Solid electrolytes transmit battery stress more than liquid electrolytes do, and research indicates that this can further contribute to shortened battery life with repeated charging and discharging. Bringing solid-state batteries to the masses will depend on finding solutions to these engineering challenges.

Ford says it can build solid-state batteries using 70% of the existing Li-ion manufacturing process. If this is true, that could be a huge leap forward. The battery-powered arms race is underway among OEMs. Whoever can unlock the extended range, quicker charging and (hopefully) greater durability of this technology will hold the key to electric dominance. But what about the elephant in the room? Tesla is on a different trajectory altogether.

Tesla’s New Battery Is an Alternative

Tesla is notably NOT interested in solid-state batteries. Their engineers even call solid-state a ‘false promise’ and a distraction. Instead, at Tesla’s Battery Day event the company shared details about their all-new battery, the 4680 lithium-ion cylindrical battery engineered with Panasonic.

The 4680 is not unlike a household D battery in size, but the engineering inside is unique. The batteries are tabless, more energy dense and far easier to make. They are cobalt-free and feature a silicon anode, two industry firsts. Tesla claims the new battery manufacturing process will enable a 100-fold increase in battery production capacity by 2030. The larger cylindrical cells fit more active battery material into the casing for a 5× improvement in energy storage and a 6× increase in power. Tesla hasn’t achieved this alone; they’ve acquired Maxwell Technologies, Grohmann, and other battery startups as they’ve partnered with Panasonic and Chinese battery leader CATL.

Will Tesla ever pivot towards solid-state batteries? As of now, it’s not in their plan.

CarEdge’s Take On Solid-State Batteries

It looks like industry experts don’t think the first mass production of solid-state batteries will happen before 2025. This technology has huge potential to disrupt the automotive industry. Imagine EVs with 500-mile ranges, excellent safety and reliability, and charging times equal to that of refueling at a gas station. But hurdles remain for automakers and the various battery startups they’ve built strategic partnerships with.

The era of EVs is already here. We’ve seen it firsthand at the 2021 LA Auto Show, and OEMs are showing how serious they are about electrification by spending lots of money on engineering and manufacturing. Today’s EVs rely on existing lithium-ion batteries. It’s all but certain that 2023-2024 models will continue to use the latest iterations of Li-ion batteries. However, once manufacturers figure out how to produce durable solid-state batteries at scale, it may turn out to be the last nail in the coffin for combustion powertrains. What do you think? Is Tesla right about the ‘false promise’ of solid-state batteries, or will Toyota and others change the game with their own new battery technology?

0 Comments